In use internationally, for thread verification and thread remediation. The most popular Thread Units in the World!

MOTORS; VOLTAGES; GEARING

A typical STH callout looks like this: STH-500-SM2-1X-12.7-R

- STH is the basic model designation.

- 500 = an ‘L’ torque unit.

- SM2 = Mitsubishi servomotor; D = direct current motor.

- 1X = direct drive; 4X = 4:1 gear reduction; 7X = 7:1 gear reduction.

- 7 (or 16) is the output shaft diameter in millimeters.

SPECIFICATIONS AND CAPACITIES FOR STH UNITS

- Cycle times shown below are for “typical” thread verification applications, with servo-driven versions, and where the thread lengths are twice the thread diameter. For very short, small diameter threads, cycles down to 0.8 seconds are possible.

- The maximum thread lengths that can be gaged are 6mm (1/4”) less than the maximum stroke figures shown. If more stroke is required, order an –ES version.

MODEL SERIES TORQUE UNIT WILL VERIFY THREAD SIZES MAX. STROKE APPROXIMATE CYCLE TIME 250-SM2-1X-12.5 S M2 – M5 (#2 thru #10) 32mm (1.25 in.) 1.5 seconds 500-SM2-1X-12.5 L M5 – M22 (#10 thru 7/8”) 32mm (1.25 in.) 2.0 seconds 2000-SM2-4X-16 XL M12 – M50 (1/2” thru 2”) 32mm (1.25 in.) 4.0 seconds 2500-SM2-7X-16 XXL M19 – M64 (3/4” thru 2-1/2”) 32mm (1.25 in.) 6.0 seconds 3000-SM2-7X-16 XXXL M50 – M100 (2” thru 4”) 38mm (1.50 in.) 7.0 seconds (for M50 size) - Additional dash-number designations:

- Add –FL for flange-mount versions.

- Add –ES suffix for extra stroke versions.

- Add –PD suffix to mount the Programmable Thread Depth Option.

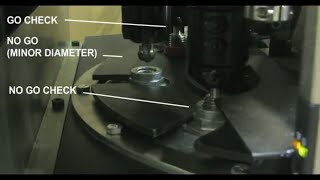

- Add –CMB suffix for “GO / NO GO” (combination gaging) versions. Also for verifying high/low thread pitch diameter limits, as with pipe threads.

- Quoted as Options:

- Slide to advance the Unit. For STH foot-mounted versions: a RAM-250 or RAM-350 Slide Unit from New Vista can be employed for this purpose.

- Programmable Thread Depth Option.

- Thread Gage Members, Thread Ring Gages, RemediationTools and Toolholders: Please order separately.

- Quickly and automatically verifies or chases threaded holes (or external threads) by powering a suitable tool into (or onto) and out of (or off of) the part. Versions are capable of “GO” gaging, “NO GO” gaging, combination gaging or thread chasing.

- Sensitive high speed drive allows the tool to stop in case of missing, short, or improperly formed threads. This creates a “reject” signal.

- Spring-biased spindle prevents damage to end of thread at start of engagement.

- Will verify blind holes (or male threads) accurately for thread depth (length). Will mount in any orientation.

- Will not jam or stick in short or obstructed (reject) threads.

- Does not subject the part (or the spindle) to high force or torque levels…even with a reject.

- A single STH Unit will work with a variety of threads. No leadscrew is employed.

- Proven out for your application before shipping.

- Shipped with complete installation instructions. Integration is simple.